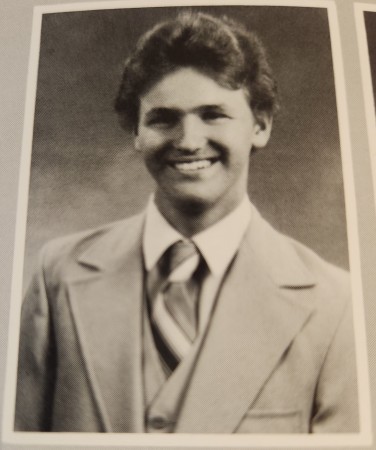

Gary Wadsworth:

CLASS OF 1981

Clyde High SchoolClass of 1981

Clyde, OH

Gary's Story

Sr. Supplier Development Engineer

Carrier · Full-timeCarrier · Full-time

Mar 2022 - Present · 1 yr 10 mosMar 2022 - Present · 1 yr 10 mos

United StatesUnited States

This Sr. Engineer position will have visibility across Carrier manufacturing plants, business units, as well

as Operation’s, Supply Chain, and Quality leadership teams for personal growth opportunities.

● Drive Carrier Supplier Excellence performance for assigned suppliers.

Supplier manufacturing quality – drive implementation of product certification (Pro-Cert) and

Quality improvements at key Carrier suppliers (maybe assigned specific commodities)

● Provide onsite guidance and coaching to key suppliers to drive improvements in performance

and championing onsite Supplier Quality Audits and Process Audits

● Design for manufacturing improvements on future products

● Support the Carrier manufacturing plants in improving PPAP completion/readiness.

● Work with suppliers to improve warranty.

● Act as a coach/facilitator for supplier quality improvement events and teaching quality tools

● Attain business objectives for quality, warranty spending, SPPM, FPY, and safety.

● Approximately 30% travel will be required (as needed)

Serving as a qualified expert in support of quality/compliance investigations, as required with

the supplier base.This Sr. Engineer position will have visibility across Carrier manufacturing plants, business units, as well as Operation’s, Supply Chain, and Quality leadership teams for personal growth opportunities. ● Drive Carrier Supplier Excellence performance for assigned suppliers. Supplier manufacturing quality – drive implementation of product certification (Pro-Cert) and Quality improvements at key Carrier suppliers (maybe assigned specific commodities) ● Provide onsite guidance and coaching to key suppliers to drive improvements in performance and championing onsite Supplier Quality Audits and Process Audits ● Design for manufacturing improvements on future products ● Support the Carrier manufacturing plants in improving PPAP completion/readiness. ● Work with suppliers to improve warranty. ● Act as a coach/facilitator for supplier quality improvement events and teaching quality tools ● Attain business objectives for quality, warranty spending, SPPM, FPY, and safety. ● Approximately 30% travel will be required (as needed) Serving as a qualified expert in support of quality/compliance investigations, as required with the supplier base.

Senior Supplier Quality Engineer

Flex · Full-timeFlex · Full-time

Jul 2020 - Mar 2022 · 1 yr 9 mosJul 2020 - Mar 2022 · 1 yr 9 mos

Clyde, Marion & Cleveland Tennessee Whirlpool PlantsClyde, Marion & Cleveland Tennessee Whirlpool Plants

Senior Supplier Quality Engineer

Responsibilities are to provide immediate response of quality complaints, perform initial failure modes assessment, coordinate failure containment activities, follow up improvement actions from our different sites, improve communication between Flex sites and Whirlpool facilities, participate in our 8D’s analysis, support our sites and Whirlpool during NPI’s execution and measure the effectiveness of actions taken at customer site.Senior Supplier Quality Engineer Responsibilities are to provide immediate response of quality complaints, perform initial failure modes assessment, coordinate failure containment activities, follow up improvement actions from our different sites, improve communication between Flex sites and Whirlpool facilities, participate in our 8D’s analysis, support our sites and Whirlpool during NPI’s execution and measure the effectiveness of actions taken at customer site.

Senior Supplier Development Engineer

Whirlpool CorporationWhirlpool Corporation

Jul 2014 - Jul 2020 · 6 yrs 1 moJul 2014 - Jul 2020 · 6 yrs 1 mo

Whirlpool Clyde DivisionWhirlpool Clyde Division

Whirlpool Laundry Clyde & Marion Plants

An EPI SDE will support supplier emergency management situations from a quality perspective. Characteristics of a typical emergency management situation at a supplier include: capacity issues, supplier unable to meet plant demand due to quality issues, alignment on visual quality standards, etc. In all of these situations, the Whirlpool plant in question is likely very close to shutting down production lines due to lack of supply or poor quality from supplier. Controlled Shipping: The purpose of this procedure is to protect Whirlpool plants from receiving non-conforming materials and parts that are not consistent with Whirlpool’s zero defect philosophy. Controlled shipping is to be implemented when a supplier has continued to ship a known failure mode to a Whirlpool plant after containment action has been identified and implemented through the use of the 8D tool. Controlled Shipping follows an escalation process from 8D to CS1 (mandated 100% sort with supplier personnel) to CS2 (mandated 100% third party sort to accompany CS1 sort). Supplier Relocations: Supplier relocation situations arise when Whirlpool shifts business from one supplier to another. This typically involves the transfer of Whirlpool-owned tools/equipment. In the case of a supplier relocation, all parts/tools that are being transferred to a new supplier must be PPAP approved. The EPI SDE will support supplier relocation events by coordinating the submission of PPAPs by the new supplier, and the approval of these PPAPs by the necessary plant SQE.Whirlpool Laundry Clyde & Marion Plants An EPI SDE will support supplier emergency management situations from a quality perspective. Characteristics of a typical emergency management situation at a supplier include: capacity issues, supplier unable to meet plant demand due to quality issues, alignment on visual quality standards, etc. In all of these situations, the Whirlpool plant in question is likely very close to shutting down production lines due to lack of supply or poor quality from supplier. Controlled Shipping: The purpose of this procedure is to protect Whirlpool plants from receiving non-conforming materials and parts that are not consistent with Whirlpool’s zero defect philosophy. Controlled shipping is to be implemented when a supplier has continued to ship a known failure mode to a Whirlpool plant after containment action has been identified and implemented through the use of the 8D tool. Controlled Shipping follows an escalation process from 8D to CS1 (mandated 100% sort with supplier personnel) to CS2 (mandated 100% third party sort to accompany CS1 sort). Supplier Relocations: Supplier relocation situations arise when Whirlpool shifts business from one supplier to another. This typically involves the transfer of Whirlpool-owned tools/equipment. In the case of a supplier relocation, all parts/tools that are being transferred to a new supplier must be PPAP approved. The EPI SDE will support supplier relocation events by coordinating the submission of PPAPs by the new supplier, and the approval of these PPAPs by the necessary plant SQE.

Senior Quality EngineerSenior Quality Engineer

Whirlpool · Full-timeWhirlpool · Full-time

Aug 2010 - Jul 2014 · 4 yrs Aug 2010 - Jul 2014 · 4 yrs

Clyde, Ohio, United StatesClyde, Ohio, United States

Senior Quality Engineer 2010 to 2014

Whirlpool Clyde Division

Design and maintains quality systems that prevent defects and validates products at various stages of production processes to ensure customer requirements are being met. Compiles and evaluates statistical data (internal and external) to determine and maintain quality and reliability of products. Interpret engineering drawings, schematic diagrams and formulas to arrive at specific quality standards for the division. Develops sampling strategies at specific stages in the production process and tests for items, such as dimensions, performance, and mechanical or electrical characteristics. Record test data using the techniques of Six Sigma and preparing data in graph and chart form. Evaluates data and writes summaries to validate and show deviations form existing standards to assist in identifying root causes and develop permanent corrective actions. In written and oral form suggests modifications of existing quality or production standards/ design, to achieve continual quality improvements. Coordinate efforts/coaching of customer assurance lab technicians for all shifts assembly line. Instrumental in establishing containment processes for finished or semi-finished product and the coordination of product rework as required. Responsible for driving improvements in Whirlpool Quality Management System, by providing training and maintaining compliance with the support of department managers. Supports Whirlpool design process, pilot builds and model line changes by providing upfront quality planning, to me...Expand for more

et and to exceed customer requirements.Senior Quality Engineer 2010 to 2014 Whirlpool Clyde Division Design and maintains quality systems that prevent defects and validates products at various stages of production processes to ensure customer requirements are being met. Compiles and evaluates statistical data (internal and external) to determine and maintain quality and reliability of products. Interpret engineering drawings, schematic diagrams and formulas to arrive at specific quality standards for the division. Develops sampling strategies at specific stages in the production process and tests for items, such as dimensions, performance, and mechanical or electrical characteristics. Record test data using the techniques of Six Sigma and preparing data in graph and chart form. Evaluates data and writes summaries to validate and show deviations form existing standards to assist in identifying root causes and develop permanent corrective actions. In written and oral form suggests modifications of existing quality or production standards/ design, to achieve continual quality improvements. Coordinate efforts/coaching of customer assurance lab technicians for all shifts assembly line. Instrumental in establishing containment processes for finished or semi-finished product and the coordination of product rework as required. Responsible for driving improvements in Whirlpool Quality Management System, by providing training and maintaining compliance with the support of department managers. Supports Whirlpool design process, pilot builds and model line changes by providing upfront quality planning, to meet and to exceed customer requirements.

Quality Project Engineer

Whirlpool CorporationWhirlpool Corporation

4 yrs 3 mos4 yrs 3 mos

Clyde, OhioClyde, Ohio

Project Quality Engineer

Jan 2008 - Mar 2010 · 2 yrs 3 mosJan 2008 - Mar 2010 · 2 yrs 3 mos

Designed, developed and coordinated, new test systems, components and current systems or processes, tool, and to facilities for an entire area or quality system within an area. Applied OPEX tools and concepts on components or processes within local site. Planned and conducted design, development coordination and/or test programs for components, systems, products and processes. Assisted in training technical staff. Analyzed, evaluated, documented data, standards and systems. Provided guidance/coordination through daily oral and written communication to subordinates, within the department and related departments. Daily /weekly contact with customers and suppliers requiring consulting and negotiations to optimize results.Designed, developed and coordinated, new test systems, components and current systems or processes, tool, and to facilities for an entire area or quality system within an area. Applied OPEX tools and concepts on components or processes within local site. Planned and conducted design, development coordination and/or test programs for components, systems, products and processes. Assisted in training technical staff. Analyzed, evaluated, documented data, standards and systems. Provided guidance/coordination through daily oral and written communication to subordinates, within the department and related departments. Daily /weekly contact with customers and suppliers requiring consulting and negotiations to optimize results.

Quality EngineerQuality Engineer

Jan 2007 - Jan 2008 · 1 yr 1 moJan 2007 - Jan 2008 · 1 yr 1 mo

Provided technical direction in problem solving while developing a strong understanding of appliance operation and basket systems. I was in a lead role in developing and improving the quality of basket systems, processes, using the OPEX and problem solving tools to determine root cause and corrective actions. I led activities that analyzed and evaluated product and processes to assure that the product is in conformance with engineering specifications, leading to improvements in the field and the divisionProvided technical direction in problem solving while developing a strong understanding of appliance operation and basket systems. I was in a lead role in developing and improving the quality of basket systems, processes, using the OPEX and problem solving tools to determine root cause and corrective actions. I led activities that analyzed and evaluated product and processes to assure that the product is in conformance with engineering specifications, leading to improvements in the field and the division

LQS Support 1st ShiftLQS Support 1st Shift

Jan 2006 - Jan 2007 · 1 yr 1 moJan 2006 - Jan 2007 · 1 yr 1 mo

As LQS I made quality decisions that supported the next customer, with strong emphasis on sustaining quality. Maintained a strong working relationship between Assembly, Supplier Quality, Engineering and Support by using tools such as 1X1 problem solving, OPEX, WQMS and control charting. By working as a Joint Problem Solving Team we understood the problems and determined root causes, developed counter measures and implemented action plans to align the Clyde Division with the “ True North Quality Strategy”As LQS I made quality decisions that supported the next customer, with strong emphasis on sustaining quality. Maintained a strong working relationship between Assembly, Supplier Quality, Engineering and Support by using tools such as 1X1 problem solving, OPEX, WQMS and control charting. By working as a Joint Problem Solving Team we understood the problems and determined root causes, developed counter measures and implemented action plans to align the Clyde Division with the “ True North Quality Strategy”

Supervisor

Whirlpool CorporationWhirlpool Corporation

21 yrs 11 mos21 yrs 11 mos

Clyde, OhioClyde, Ohio

Supervisor- Plastics, Machine Shop, Line 2, 3, 4, ReworkSupervisor- Plastics, Machine Shop, Line 2, 3, 4, Rework

Feb 1997 - 2005 · 8 yrsFeb 1997 - 2005 · 8 yrs

Responsible for productivity, quality and human resource issues. Tracked downtime, created action plans, tracked the budget and scrap. Tracked repair bay, CAL defects. Coordinated voluntary layoffs and manpower moves due to bids or cutbacks. I enforced all blue book policies and tracked absenteeism. I communicated nightly, utilizing a newsletter. I participated in Consumer Centered Manufacturing, CCM overview, 5S/VC, Cell Design Wave ll. I played an active role in motivating teams toward the goals and objectives of the Clyde Division.Responsible for productivity, quality and human resource issues. Tracked downtime, created action plans, tracked the budget and scrap. Tracked repair bay, CAL defects. Coordinated voluntary layoffs and manpower moves due to bids or cutbacks. I enforced all blue book policies and tracked absenteeism. I communicated nightly, utilizing a newsletter. I participated in Consumer Centered Manufacturing, CCM overview, 5S/VC, Cell Design Wave ll. I played an active role in motivating teams toward the goals and objectives of the Clyde Division.

Quality Advisor – Line 2 and 4 1st and 2nd ShiftsQuality Advisor – Line 2 and 4 1st and 2nd Shifts

Jan 1996 - Jan 2002 · 6 yrs 1 moJan 1996 - Jan 2002 · 6 yrs 1 mo

Responsible for meeting all repair bay, CAL, and quality objectives and monitoring day to day operations. I attended weekly EN meeting, followed up on all repair bay, CAL defects, and created action plans to address repeat offenders. I attended monthly quality advisor meetings and weekly Quality Improvement meetings to reduce scrap. I communicated nightly utilizing a newsletter. I played an active role in motivating teams toward the goals and objectives of the Clyde DivisionResponsible for meeting all repair bay, CAL, and quality objectives and monitoring day to day operations. I attended weekly EN meeting, followed up on all repair bay, CAL defects, and created action plans to address repeat offenders. I attended monthly quality advisor meetings and weekly Quality Improvement meetings to reduce scrap. I communicated nightly utilizing a newsletter. I played an active role in motivating teams toward the goals and objectives of the Clyde Division

Productivity Advisor- Line 2 and 4 1st 2nd and 3rd ShiftsProductivity Advisor- Line 2 and 4 1st 2nd and 3rd Shifts

Jan 1997 - Jan 2000 · 3 yrs 1 moJan 1997 - Jan 2000 · 3 yrs 1 mo

Responsible for daily production of the line. My duties included overseeing 10x and 5% TCP, TPM, and each lines yearly budget. I served as the adviser to all the teams in the departments I advised. I was responsible for setting goals and agendas for productivity as well as all-star point teams. I attended monthly Productivity advisor meetings and weekly Productivity Improvement meetings to reduce downtime. I communicated nightly utilizing a newsletter. I played an active role in motivating my teams toward the goals and objectives of the Clyde Division

Register for Free to view all details!

Reunions

Photos